Curved Glass

Curved glass is a type of glass that has been heated to a high temperature and then shaped or bent to a specific curvature. It is typically made from tempered or laminated glass, which are strong and durable materials.

Curved glass can be used in a variety of architectural and design applications, including building facades, skylights, aquariums, furniture, and automotive windows. It can also be used in electronic devices such as curved televisions and smartphones.

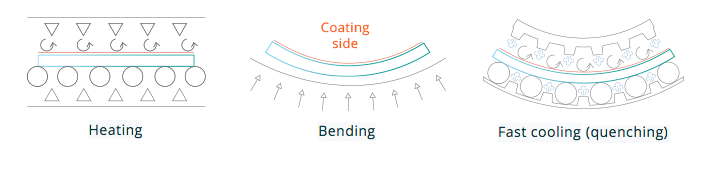

Making curved glass involves heating it to a high temperature and then placing it on a mold to cool it and take on the desired shape. The cooling process is carefully controlled to ensure that the glass maintains its strength and integrity.

The major benefits of toughened glass are:

Process:

This process introduces stresses in the glass, improving its overall material strength.

While not as versatile as annealed curved glass, toughened glass employs a faster production process and enables the use of the best Energy Efficient coatings such as Low-E and High Selectivity coatings. Heat strengthened glass is very similar and produced in the same oven, but quenched more slowly.

Specification:

Thickness:

6mm 8mm 10mm 12mm 15mm 19mm

Shape and Size:

Flat, Custom Shape

Min. 200x300mm

Max. 2400mmx42000mm

Color:

Clear, Tinted, Frosted, Reflective, Low-e Coated

Application:

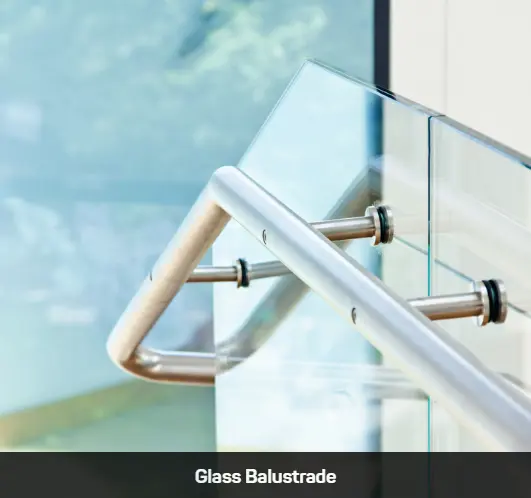

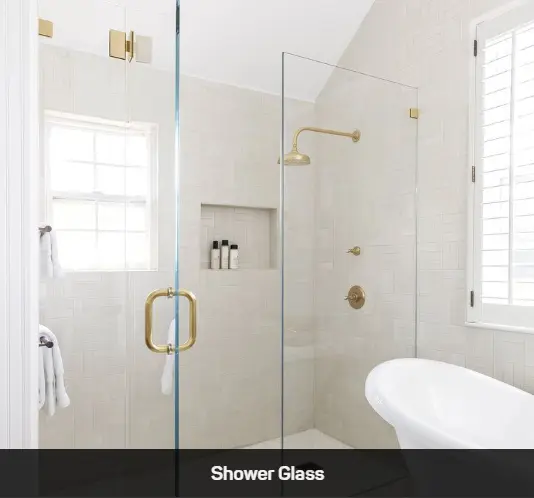

Facades, railings, Partition walls, shower cabins, doors, and the like.

Delivery time:

7-15 days, urgently service is available.

Characteristics

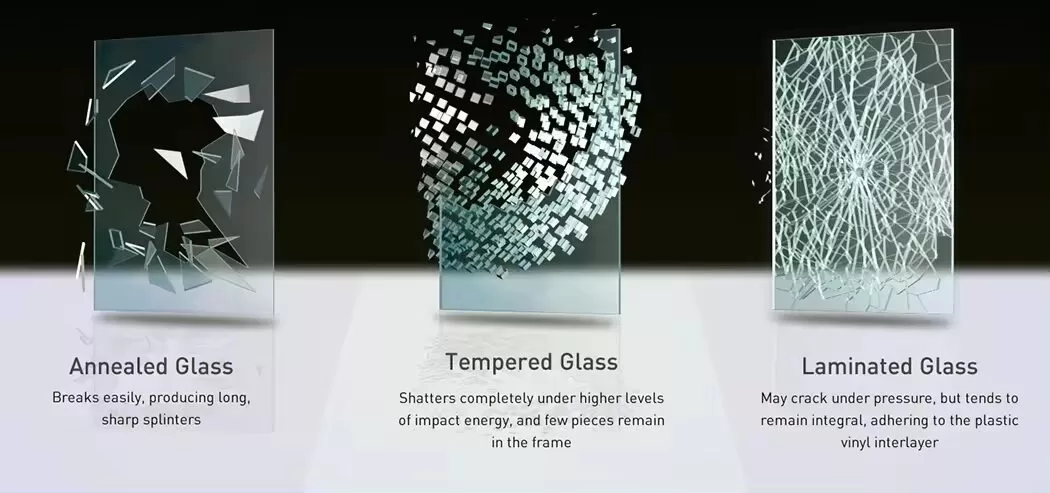

The three commonly used types of bent glass are

Curved annealed glass

Often employed for showcasing purposes where strength and safety are of lesser concern.

Curved laminated glass

Curved laminated glass: Formed by bonding two layers of glass, it is highly durable. When shattered, it remains within the lamination, reducing the risk of sharp shards.

Curved tempered glass

Curved tempered glass: Renowned for its strength and shock resistance, this glass is produced by heating annealed glass to 700°C and then rapidly cooling it. The resulting tensile and compressive stresses render the glass very robust. When broken, it fractures into tiny, less hazardous pieces, minimizing the risk of injury from falling shards.

Explore Our Products

With over 55 years of dedication, our business stands at the forefront of the Aluminum and Glass industry. From humble beginnings in the 1960s to four cutting-edge facilities spanning thousands of square feet, our commitment to precision and innovation remains unwavering. Backed by seasoned engineering and meticulous manufacturing processes, we deliver excellence with every product, embodying a legacy of reliability and expertise.